|

�

Keeps the air gently gliding through your ductwork and past the

Air Probe Sanitizer UV-C lamps. Because the fan never stops (just slows down to very slow), the ultraviolet

lamps are always doing their job zapping slow-moving contaminants.

Very useful in northern climates in the spring and fall months when

the air conditioner/furnace blower fan does not run. Very useful in northern climates in the spring and fall months when

the air conditioner/furnace blower fan does not run.

When the FanHandler is operating, the average blower speed is much slower. This

allows more time for UV lights to kill germs and mold spores. In many cases, the "kill time" of the

UV rays from the Air Probe Sanitizer probes can be vastly increased. Your filters work about three times

more efficiently. And, a super important point is that during air conditioning, much more moisture is

removed from your home and it is much less likely to be blown off the A/C coil and into the ductwork

where it can provide a great environment for mold.

�

�

Can actually help save energy. The FanHandler, when running

a quality blower motor at half-speed, (which it does most of the time) will use about one eighth the

electricity that it takes to run the same motor at full speed. In other words you can run the FanHandler

controlled motor eight hours for the same amount of money that you can run the same motor for one hour

at full speed. But don't buy one for the energy savings, buy it for healthy indoor environmental quality

(through increased Air Probe Sanitizer and filter efficiency), and comfort. Can actually help save energy. The FanHandler, when running

a quality blower motor at half-speed, (which it does most of the time) will use about one eighth the

electricity that it takes to run the same motor at full speed. In other words you can run the FanHandler

controlled motor eight hours for the same amount of money that you can run the same motor for one hour

at full speed. But don't buy one for the energy savings, buy it for healthy indoor environmental quality

(through increased Air Probe Sanitizer and filter efficiency), and comfort.

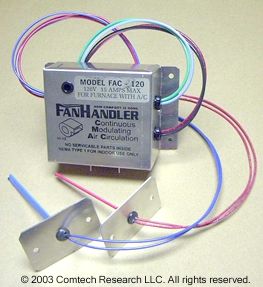

The model FAC-120 (120 volts, 15 amps max.) senses either hot

or cold air in the furnace/AC plenum or duct, and speeds up the fan as required. The fan returns to

minimum speed (user-adjustable) afterwards, as illustrated here. (Use HP-120 or HP-240 for heat pumps).

�

The FanHandler is very durable and reliable. All FanHandler products are tested

during the manufacturing process at least three times on actual residential-type blowers.

WARRANTY:

FanHandler CONTROLS CARRY A FIVE-YEAR MANUFACTURER'S LIMITED WARRANTY ON PARTS

AND WORKMANSHIP (excludes mishandling, abuse, misapplication, or any costs for removing and replacing

the installed control). Effective 10/1/03

PRICES:

Available from your dealer. The FanHandler is

available at a discount only if purchased with an

Air Probe

Sanitizer. Price breaks are available for case quantities of 12 and 48 units.

Mix or match for quantity FanHandler discounts. Prices do not include

installation or shipping.

�

FanHandler specification and information documents in PDF format: FanHandler specification and information documents in PDF format: |

Info sheet #1*.� (The schematic there shows it wired into the existing fan relay, but that is not

necessary (or possible) on some systems). Info sheet #1*.� (The schematic there shows it wired into the existing fan relay, but that is not

necessary (or possible) on some systems).

� |

Info sheet #2 Info sheet #2

|

*The schematic diagram in info sheet #1 has been a little confusing

to some people. Here are some clarifications.�

The FanHandler is usually installed simply as follows:

(model FAC-120)

- Cut the white fan motor common wire (neutral). Connect the two resulting wire ends as follows:

- Connect the FanHandler's red wire to the white wire coming from the motor (motor common).

- Connect the FanHandler's black wire to the remaining white wire (neutral).

- Connect the FanHandler's green wire to ground.

- Connect the FanHandler's blue wire to the hot wire (L1, usually black).

Turn the FAN switch on the wall thermostat from the AUTO to

the ON position. The schematic indicates a normally-closed motor

relay on the system's fan controller board. When the system is not calling for

heat/cool, then it is ONLY closed when the FAN switch is ON (on many systems).

LEAVE THE FAN SWITCH IN THE ON POSITION.

Replace the phrase "motor common" or "fan motor common" at the bottom of the schematic with the phrase

"neutral (former fan motor common), white".

Connect the temperature sensors in the directions furnished with each FanHandler (below) for

adjusting the blower speed, etc.

|

The FanHandler, like the Air Probe Sanitizer, is to be installed only

by a qualified person, such as your local licensed HVAC (Heating, Ventilating, and Air Conditioning)

professional, IAQ (Indoor Air Quality) professional, or licensed electrician.

INSTALLATION & OPERATION OF

FanHandler controls

For use on P.S.C. or shaded pole motors used to drive direct-drive

fans and blowers. SENSORS FOR FAC-120 AND FAC-240 SERIES FanHandler CONTROLS

- AC/Furnace: FAC-120

& FAC-240 SUPPLIED WITH 1-RED & 1 BLUE SENSOR

- Heat pump: HP-120 & HP-240 SUPPLIED WITH 1-YELLOW & 1 BLUE SENSOR

- LA-120 & LA-240 SUPPLIED WITH 1-YELLOW SENSOR.

- 120-15 & 240-8 SUPPLIED WITH 1-RED SENSOR (heating only) OR 1 BLUE

SENSOR (cooling only) NOT STOCKED. WE SUGGEST USING THE FAC-120 AS BELOW.

- O-1Ovdc-120 & O-1Ovdc-240 NO SENSORS

FanHandler controls are ETL listed for field or factory installation under

file #114704-322 as conforming to ANSI/UL-508 and CAN/CSA C22.2 NO. 14. Installation and wiring

must comply with all local and national electrical codes.

Only qualified HVAC technicians and service mechanics may install or adjust the FanHandler motor speed

control.

�

|

TO OPERATE THE FAC-120 ON EITHER� HEAT ONLY

OR COOL ONLY SYSTEMS

|

| For air handlers with air conditioning only, and no heat: Leave

the two red sensor wires disconnected, and do not use the red (heat) sensor supplied.

For air handlers with heat only (furnaces with no air conditioning): Connect

the two blue sensor wires together, and do not use the blue (cooling) sensor supplied.

|

INSTALLATION

1. DISCONNECT POWER TO THE EQUIPMENT

2. Check operating voltage of fan, and make certain that the control

is of the proper voltage and type.

3. Mount the FanHandler in a location safe from weather, moisture

or excessive heat. Normally this is inside the fan compartment, mounted on or near the blower.

4. Locate sensors

in the supply duct

were they will sense a representative sample of the air temperature being delivered to the conditioned

space. This is done by drilling a 1/2" holes in the proper locations and fastening sensors to duct with

two sheet metal screws each. Do not locate sensors a long distance down the duct from the heating and

cooling source. This may result in the fan speed lagging the actual output. Route low voltage sensor

wires away from high voltage wiring. Wire sensors to corresponding colored sensor wires (blue sensor

to blue wires, red sensor to red wires and yellow sensor to yellow wires).

5. Wire the FanHandler in series with the fan motor. Several wiring

diagrams are included as examples.

6. Double check wiring, then reapply power to the system.

Turn the Fan AUTO/ON switch on the wall thermostat to ON and leave it

there.

7. Set minimum speed.

Minimum speed

is adjusted by turning the potentiometer located behind the small hole in the upper left hand corner

of the front of the box with a small screwdriver. Turning the pot clockwise increases the minimum speed,

and turning the pot counter clockwise lowers the minimum speed. Set the minimum speed as high as possible,

without causing uncomfortable drafts. Setting the minimum speed too low (although impressive) does not

properly mix the air in the home and will produce unwanted results. A rule of thumb: set minimum speed

so that the furthest run will move a tissue but not cause a draft a foot from the register. The minimum

speed adjustment is for setup and fine-tuning only, it should be set and left alone. If the owner wants

to temporarily override or change the speed of the fan after installation, then a remote speed selector

should be installed (see later in the instructions). That way your original setting is maintained while

allowing the customer to override the speed as desired.

8. Verify operation.

Allow the system

to balance out so it is delivering about 72 degrees and is neither calling for heating nor cooling. Then set

the thermostat to call for heat, as the temperature rises in the duct, the fan speed should increase.

Set the thermostat to shut the heat off and observe that as the delivered air temperature drops, the

fan speed will decrease to your PRE-SET minimum speed. Then set the thermostat to call for cooling,

as the temperature in the duct drops the fan speed will increase and hit top speed at about 50

degrees delivered

temperature. Turn thermostat up turning off the air conditioner. Observe that while the temperature

in the duct approaches room temperature, the FanHandler control will smoothly decrease the fan speed

back to your minimum speed setting.

IMPORTANT -- MOTOR SELECTION

If you or your customer is unwilling to replace an incompatible motor, we recommend

that you not purchase or install FanHandler controls.

You will

occasionally encounter direct drive fan motors built to meet a price rather than a quality criteria.

These motors do not contain adequate copper windings or iron laminates to allow the motor to follow

the fan laws when reducing speed. These motors are usually constructed to loose stator to rotor spacing

tolerances. Or a motor on the job might have been banging on and off for years and not oiled so the

bearings are worn. If a motor heats-up and/or growls at low speed, or if the current increases

as the speed is adjusted from maximum to a lower speed, then it should be replaced with a high

quality motor designed for general use. Quality is the only factor in determining a motor's fitness

for speed regulation. Determine motor fitness on a case by case basis. It is impractical for us to keep

up with changes that equipment manufacturers make in the motors that they install. Baldor is building

a high quality, commercial/industrial quality, motor to our specifications. We offer these direct-drive

motors to FanHandler contractors.

In our experience, the motor does not usually have to be replaced

in most installations. But if it does, we offer the motors at just above our wholesale cost to our

FanHandler customers. Please note that these motors are special order, since we get very few

orders for them.

�

Motor Power Requirements & Operation Cost Formulas

DEFINITIONS:

S = Speed = RPM = Revolutions Per Minute.

CFM = Cubic Feet Per Minute.

W = Watts = Electrical unit of power.

HP = Horsepower = Mechanical unit of power.

1 HP = 745 Watts = Conversion of electrical power to mechanical power.

Fan Laws:

CFM2 = CFM1 x RPM2/ RPM1 or CFM is directly pegged to rpm.

If RPM is cut in half then CFM is also cut in half. If 1,040 RPM produces 1,200 CFM

then 520 RPM will produce 600

CFM.

HP @ S2 = HP @ S1 x (RPM2 / RPM1)2 This demonstrates that

the horsepower required to turn the fan is related to the square root of the speed change. Or if the

fan's speed is cut in half, then the amount of air delivered is also cut in half but the Horsepower

required is only 1/4 of the original Horsepower required. OR, a fully loaded 1/2 HP fan

motor running at 1,040 RPM and producing 1,200 CFM will only require 1/8 HP to deliver 600 CFM at 1/2

speed of 520 RPM. This demonstrates that the power required to turn the fan reduces a lot faster than

the reduction in CFM being delivered.

WATTS2 = WATTS1 x (RPM2/RPM1)3 or WATTS2 = WATTS1 (CFM2/CFM1)3

This demonstrates that the electrical power required to turn the fan drops by the cube of the speed

change. Or drop the speed (RPM) in half and the Power (Watts) required is 1/8 the original power required.

Our example:1/2 HP fully loaded fan motor running at 1,040 RPM and delivering 1,200 CFM requires 745

watts/2 or 372.5 Watts. Cut this motor's speed in half and you cut the air delivery in half, but the

Wattage required is 372.5/8 = 46.6 Watts.

Therefore, a fan motor must run 8 hours at half speed to use the same amount of

electricity as it would running at full speed for 1 hour.

Now lets bump this up against reality. Lets assume that our example fan

is in an average furnace. On an average winter day it runs about 1/2 of the time. It therefore uses

372.5 watts / 2 = 186 watt-hours of electricity. Now we install a FanHandler that runs the fan full

time. Now lets say there is a call for heat 3 times during that hour and the fan reaches top speed three

times for 3 & 1/3 minutes each time (which it probably won't) 10 minutes per hour = 1/6 hour x 372.5

watts = 62 watts and the other 50 minutes it uses 5/6 of 46.6 watts = 38.83 watts for a total of 38.8

+ 46.6 =100 watts per hour. For a savings of 86 watt-hours. And the home is comfortable, the air cleaner

or filters are working full-time at much higher efficiency.

Monthly cost for the FanHandler equipped fan at $0.10 per KWH = 86 watt

hours x 24 hours x 30 days per month = 61,920 watt-hours or 61.9 KWH x $0.10 = $6.19 per month. If you

ran the full-speed fan round the clock, it would cost 372.5 watts X 24 hours = 8.9 KW = $0.89 per day

X 30 days per month = $26.00 per month. If you ran the full-speed fan 1/2 the time it would cost $13.00

per month. You can use your electricity costs and horsepowers etc. to do the comparisons. It will prove that the FanHandler saves energy!!

Simply put, you can run the fan eight hours at half speed for

the same cost as running it one hour at full speed.

�

THE IN-DUCT TEMPERATURE SENSORS (2)

The sensors are actually thermistors (resistors that change value as the

temperature changes). They are the small shiny black beads at the tip.*

Like the FanHandler, they are very reliable. If you should ever want to test

them, here are the approximate resistance readings at 62 degrees F. (a

typical value with the air conditioner running):

�Blue probe: 7K Ω (cold air

sensor)

� Red probe: 45K Ω

(hot air sensor)

At temperatures other than 62 degrees, these readings will be different.

These are values of

sensors supplied with the FAC-xxx models, for reference.

* DO NOT bend or pick at the tiny

black shiny bead at the tip of the sensor probe. You can break the tiny

wires, rendering the probe useless. A nominal charge will be made for a

replacement probe damaged in this way.

�

FOR PROFESSIONAL INSTALLATION BY QUALIFIED PERSONS

ONLY.

For good reasons, we do NOT sell the FanHandler

directly to the consumer, and so the price is not advertised here. HVAC and IAQ professionals, please call us for pricing

and ordering information. We're

sorry for any inconvenience this may cause.

�

�

FanHandler�

Continuously Modulating Air Circulation

How Comfort Is Done

�

Back to Air Probe Sanitizer main page

|

Very useful in northern climates in the spring and fall months when

the air conditioner/furnace blower fan does not run.

Very useful in northern climates in the spring and fall months when

the air conditioner/furnace blower fan does not run.  Can actually help save energy. The FanHandler, when running

a quality blower motor at half-speed, (which it does most of the time) will use about one eighth the

electricity that it takes to run the same motor at full speed. In other words you can run the FanHandler

controlled motor eight hours for the same amount of money that you can run the same motor for one hour

at full speed. But don't buy one for the energy savings, buy it for healthy indoor environmental quality

(through increased Air Probe Sanitizer and filter efficiency), and comfort.

Can actually help save energy. The FanHandler, when running

a quality blower motor at half-speed, (which it does most of the time) will use about one eighth the

electricity that it takes to run the same motor at full speed. In other words you can run the FanHandler

controlled motor eight hours for the same amount of money that you can run the same motor for one hour

at full speed. But don't buy one for the energy savings, buy it for healthy indoor environmental quality

(through increased Air Probe Sanitizer and filter efficiency), and comfort.